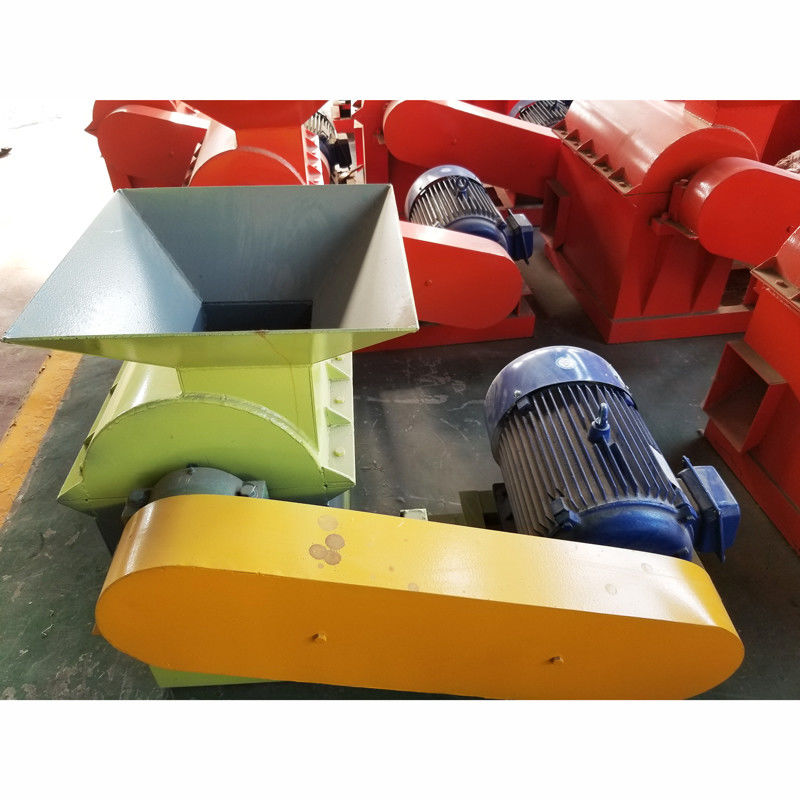

Chicken Dung Manure Crusher Half Wet Materials Pulverizer Machine for Fertilizer

Semi-wet material pulverizer is a professional pulverizing equipment for professional pulverizing high humidity and multi-fiber materials. The semi-wet material pulverizer uses a high-speed rotating blade to pulverize the fiber with good particle size, high efficiency and high energy. The semi-wet material pulverizer is mostly used in the production and processing of organic fertilizer, and the smashing of chicken manure, humic acid and other raw materials has a good effect.

Performance characteristics:

1.The semi-wet material crusher has flexible combination and strong applicability.

2.The semi-wet material crusher does not have any requirement for the moisture content of the material. Without the sieve bottom and the screen mesh, the material with high moisture content can be pulverized, and the viscous material with relatively high viscosity will not be clogged.

3.The semi-wet material crusher uses a high-alloy wear-resistant hammer head. The hammer piece is made of forged, which is particularly strong and wear-resistant. It is stronger than the ordinary hammer and increases the service life of the hammer piece.

4.The semi-wet material crusher adopts the gap-fixing technology. When the hammer head is worn, the position of the hammer head is adjusted to reduce the gap between the hammer and the lining. This will give you a satisfactory graininess.

| Model |

Power(kw) |

Capacity(t/h) |

Crushing Granularity(mesh) |

Inlet Size(mm) |

Dimensions(mm) |

| TDSF-40 |

22 |

1-1.5 |

50 |

400*240 |

1200*1350*900 |

| TDSF-40Ⅱ |

22*2 |

1-1.5 |

80 |

400*240 |

1250*1600*1300 |

| TDSF-60 |

30 |

1.5-3 |

50 |

500*300 |

1300*1450*1300 |

| TDSF-60Ⅱ |

30*2 |

1.5-3 |

80 |

500*300 |

1500*2150*1920 |

| TDSF-90 |

37 |

3-5 |

50 |

550*410 |

1800*1550*1700 |

| TDSF-120 |

75 |

5-8 |

50 |

650*500 |

2100*2600*2130 |

Working principle:

The semi-wet material pulverizer adopts the two-stage rotors, that means up and down two-stage pulverization. When he raw material passes through the upper-stage rotor pulverizer to form a coarse particles, and then is transported to the lower-stage rotor to continue pulverization into fine powder to reach the best particle sizes for the next granulating device. There is no sieve mesh at bottom of the semi-wet material pulverizer. wet materials can be crushed and never blocked. Even materials that have just been taken from the water can be crushed, and no worry about clogged or blocked.

FAQ:

1. Are you trading company or manufacturer ?

We are a manufacturer with a history over 40 years and have realized one-stop service for design, manufacture, installation, debugging and technical training.

2. How long is the delivery time?

For standard machines or Components, it would be 5-10 days; For non-standard machines and customized machines according to clients specific requirements, it would be appointment time.

3. Do you arrange shipment for the machines?

Yes, we will do that. For FOB or CIF price, we will arrange shipment for you. For EXW price, we will assist you in arranging shipment.

4. How about your product after-sales service?

Normally we provide video and written technical support. If necessary, our engineers can also provide on-site service. Our product accessories can be selected according to the actual needs of the customer to choose the most appropriate way to deliver.

5. What kinds of certificate you have?

ISO 9001: 2015 SGS and we can make other certificates according to customers' detailed requirements.

6. How to guarantee the quality and operation before loading?

We have our own quality control department and have advance quality control stystem while from raw materials to finished products. All the machines and production lines shall be 100% checked and tested before delivery.

Twoja wiadomość musi mieć od 20 do 3000 znaków!

Twoja wiadomość musi mieć od 20 do 3000 znaków! Proszę sprawdzić email!

Proszę sprawdzić email!  Twoja wiadomość musi mieć od 20 do 3000 znaków!

Twoja wiadomość musi mieć od 20 do 3000 znaków! Proszę sprawdzić email!

Proszę sprawdzić email!